Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

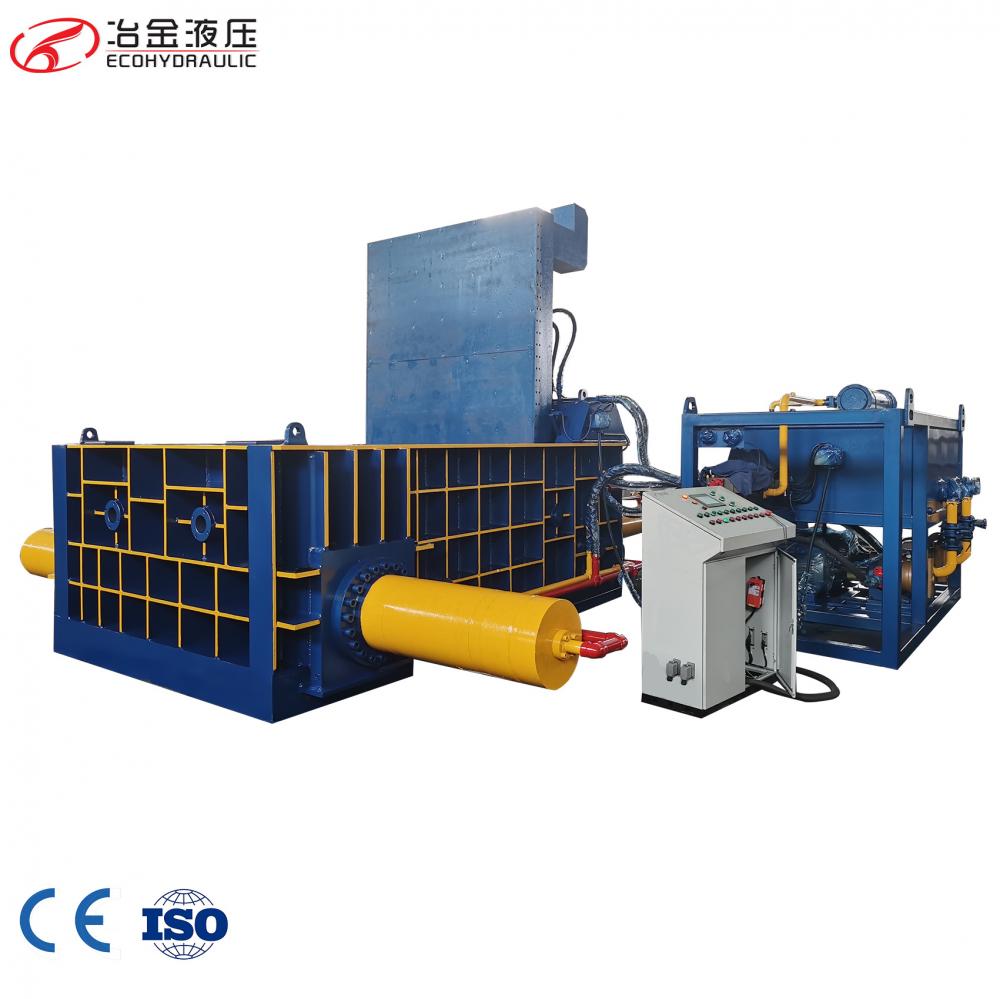

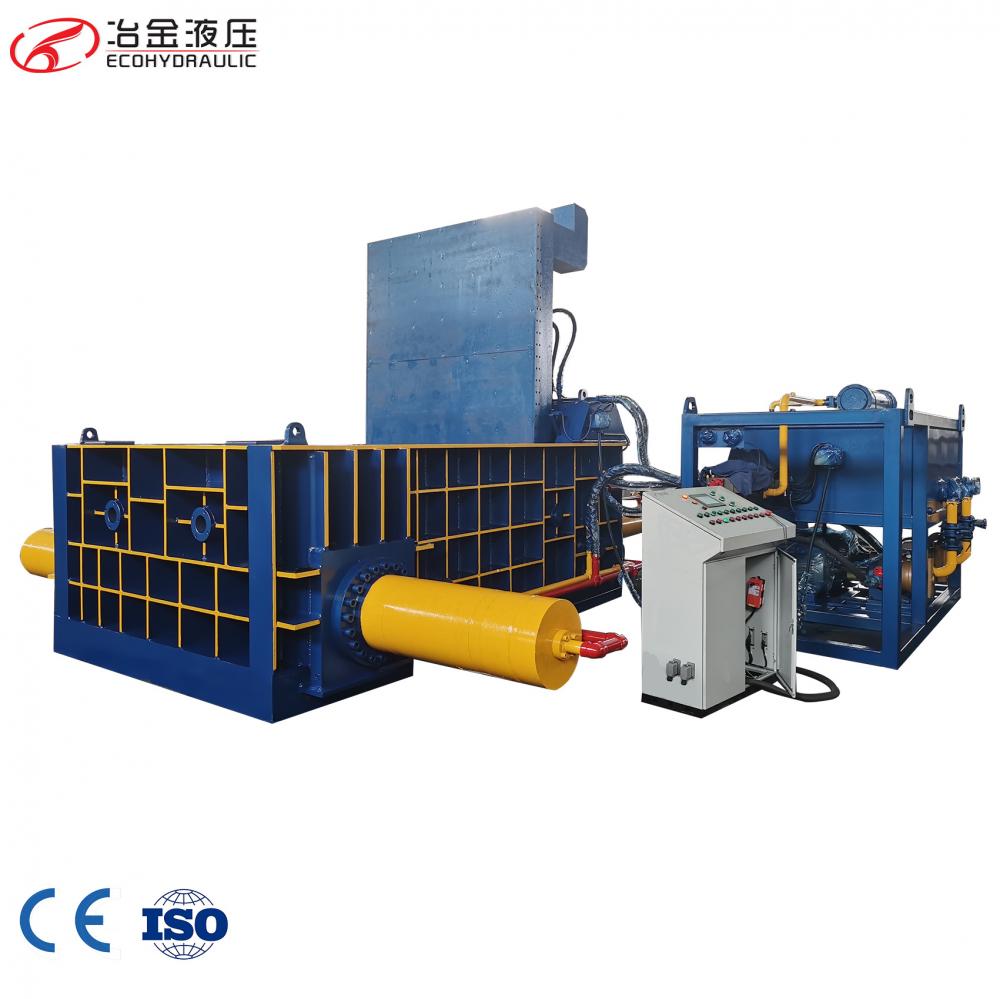

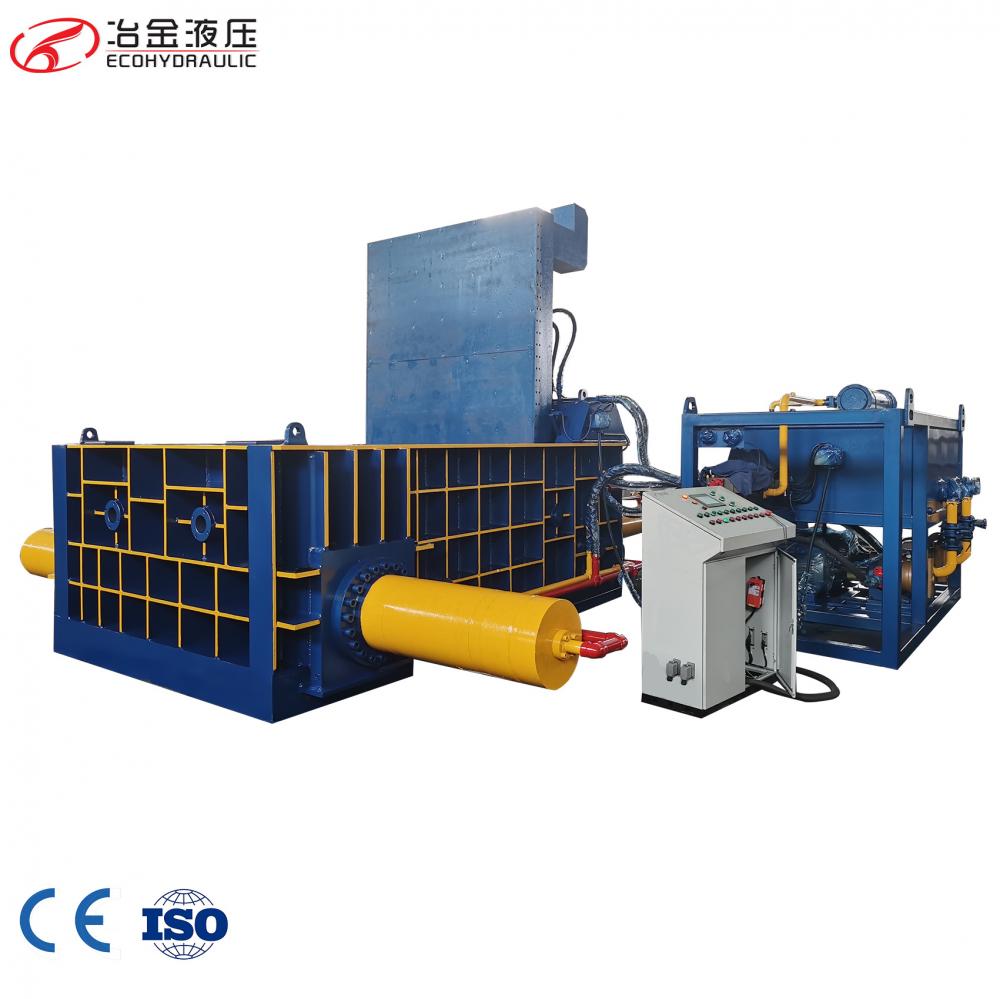

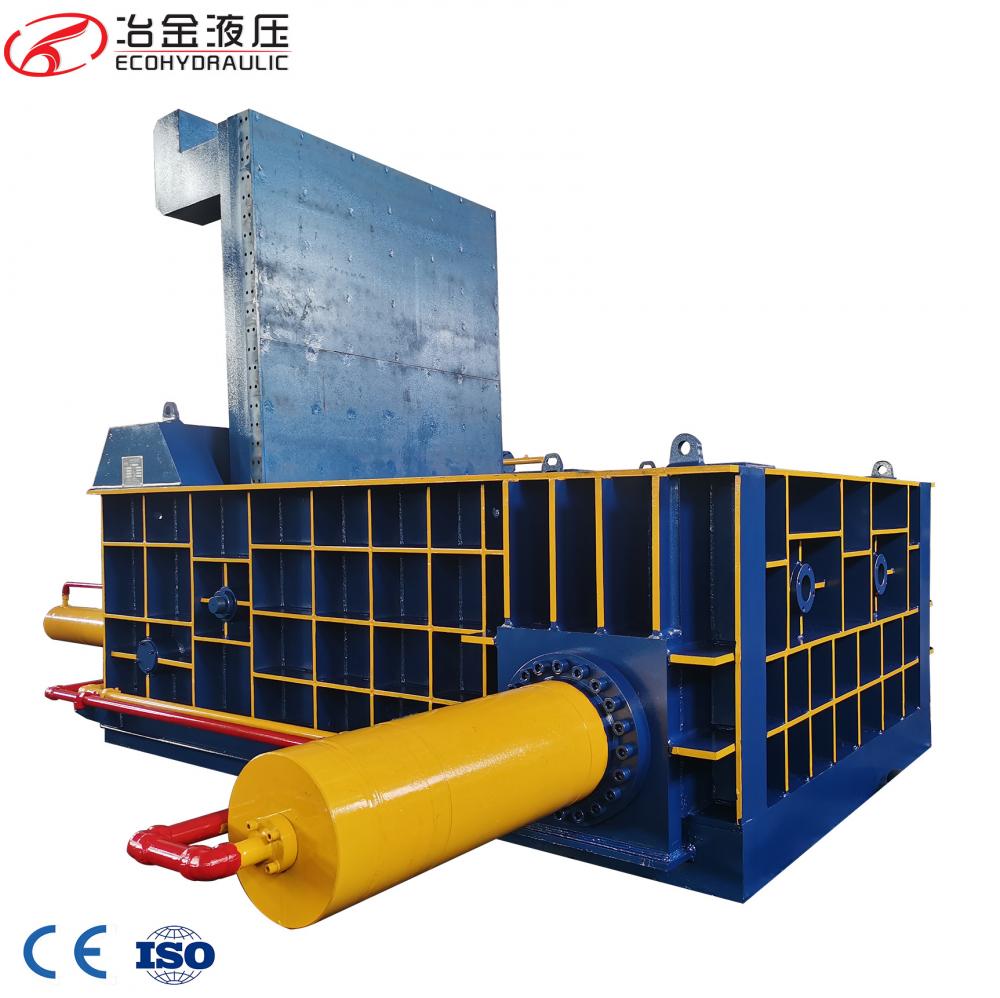

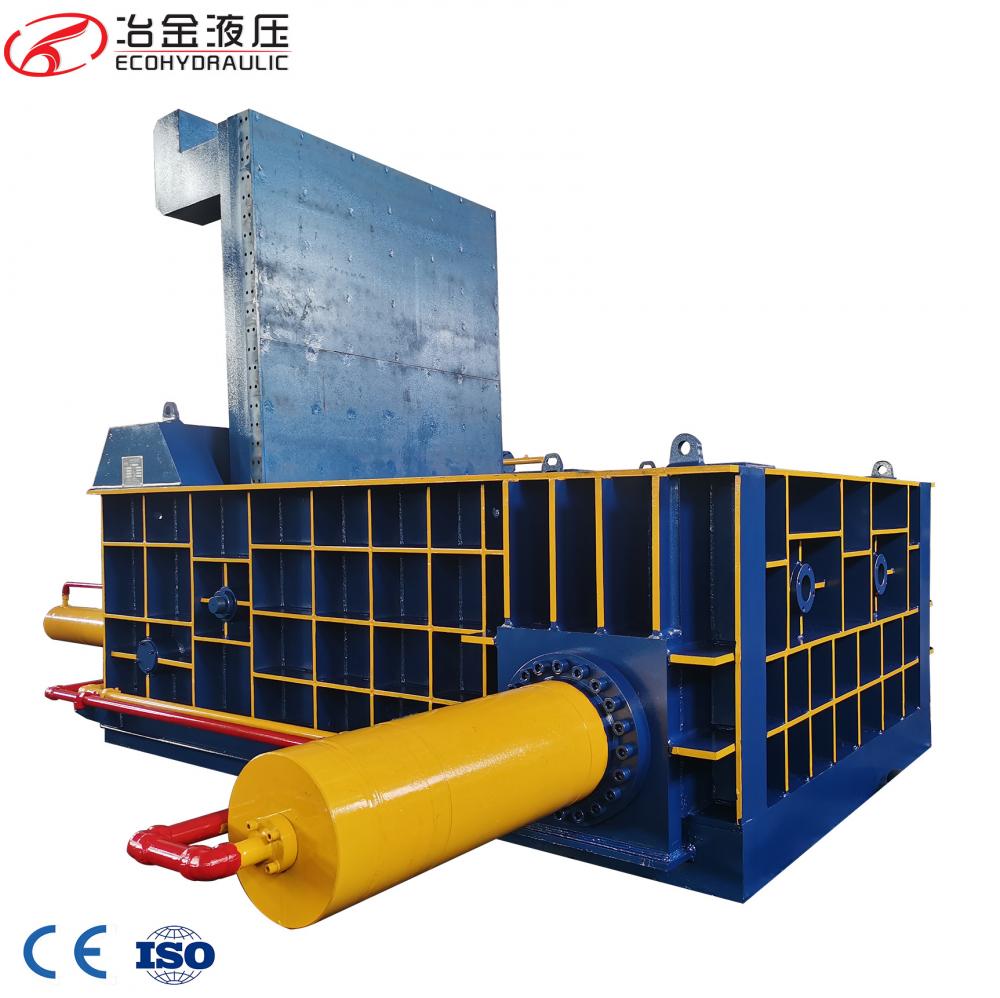

Introducing our revolutionary Hydraulic Aluminium Profile Scrap Steel Block Making Machine! Designed to streamline your scrap steel recycling process, this cutting-edge machine is built with high-quality hydraulic components and a sturdy aluminium profile frame, ensuring durability and long-lasting performance. With its advanced technology, this machine efficiently transforms scrap steel into solid blocks, reducing waste and maximizing your recycling efforts. Its user-friendly interface allows for easy operation and precise control, while its compact design saves valuable space in your facility. Invest in this innovative solution today and witness a significant boost in your scrap steel recycling efficiency.

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

Introducing our revolutionary Metal Press, designed to efficiently process Copper Shavings, Steel Turnings, and Aluminum Cans. This state-of-the-art machine boasts cutting-edge technology, guaranteeing superior performance and productivity. With its robust construction and precision engineering, our Metal Press ensures seamless compression of these materials, resulting in reduced waste volume and increased recycling efficiency. By transforming these metal scraps into compacted blocks, our Metal Press not only optimizes storage space but also enables easy transportation and subsequent recycling. With its user-friendly interface and advanced safety features, this indispensable tool is a game-changer for industries dealing with metal waste. Maximize your environmental responsibility and operational efficiency with our Metal Press.

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

Introducing our Scrap Steel Waste Oil Drums Metals Hydraulic Baler, a powerful and efficient solution for recycling and managing waste materials. Designed with precision engineering, this baler effortlessly compresses and compacts scrap steel, waste oil drums, and various metal materials, reducing their volume and facilitating easy transportation. Equipped with a robust hydraulic system, it ensures smooth and reliable operation, while the durable construction guarantees long-lasting performance. Our baler not only saves valuable storage space but also contributes to the preservation of our environment by promoting responsible waste management. Invest in our Scrap Steel Waste Oil Drums Metals Hydraulic Baler and experience unparalleled efficiency and sustainability in waste handling.

Save time! Get the best deal

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

Introducing the "Ironator 3000" - the ultimate solution for professionals tired of wrestling with those pesky light metal iron sheets scrap! Say goodbye to sore muscles and hello to effortless scrap car baling. This magnificent machine is like having the Hulk as your personal assistant - it crushes, compresses, and molds those stubborn metal sheets into compact, manageable blocks with the precision of a surgeon. It's so efficient that you'll have time to sip your coffee, catch up on the latest gossip, and even practice your dance moves while the Ironator 3000 does all the heavy lifting. Get ready to transform scrap into scrap-tastic!

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

Introducing the revolutionary Ziptop Can Compressing Machinery Scrap Iron Aluminum Baler, the ultimate solution for efficient and eco-friendly waste management. This state-of-the-art baler is designed to effortlessly compress and compact scrap iron and aluminum cans, reducing their volume by up to 90%. With its advanced technology and robust construction, this machinery ensures maximum durability and longevity. Its user-friendly interface allows for easy operation, while its high-speed performance guarantees swift processing, saving you valuable time and resources. Say goodbye to cluttered spaces and hello to organized waste management with the Ziptop Can Compressing Machinery Scrap Iron Aluminum Baler.

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

Introducing our revolutionary Push-out Aluminum Copper Steel Iron Chips Metal Compactor! Designed to streamline waste management processes, this compact and efficient compactor is perfect for industrial settings. It effectively compresses and compacts various metal chips, ensuring maximum utilization of storage space and reducing disposal costs. With its sturdy construction and powerful hydraulic system, this compactor effortlessly handles aluminum, copper, steel, and iron chips, minimizing manual labor and enhancing productivity. Its push-out mechanism simplifies the removal of compacted materials, allowing for easy transportation and recycling. Invest in our Push-out Aluminum Copper Steel Iron Chips Metal Compactor and experience unparalleled efficiency in your metal waste management operations!

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

Introducing the Scrap Round Steel Pipe Rebar Iron Baling Machine, the ultimate solution for efficiently managing and recycling metal waste! This powerful and durable machine is designed to effortlessly compress and bale scrap round steel pipes, rebar, and iron, minimizing storage space and optimizing transportation. With its advanced technology and high-pressure hydraulic system, this baling machine ensures maximum compaction, resulting in tightly packed, uniform bales that are easy to handle and transport. Its user-friendly interface allows for simple operation and customization, while its robust construction guarantees long-lasting performance. Don't miss out on this must-have tool for any metal recycling facility or scrap yard. Invest in the Scrap Round Steel Pipe Rebar Iron Baling Machine today and revolutionize your metal waste management process!

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

Introducing our Hydraulic Automatic Used Metal Chips Aluminum Sheets Baler, the ultimate solution for efficient waste management in industrial settings. This powerful machine is designed to compress and bale metal chips and aluminum sheets, reducing their size and maximizing storage space. With its automatic operation, it eliminates the need for manual labor, saving time and increasing productivity. Equipped with a robust hydraulic system, it ensures smooth and reliable performance. Its durable construction guarantees long-lasting use, while its user-friendly interface makes operation simple and hassle-free. Invest in our Hydraulic Automatic Baler to optimize your waste management process and achieve significant cost savings.

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

Introducing our Scrap Iron Cans Sheets Pipes Tubes Baling Machine, the perfect solution for efficiently compacting and baling various scrap iron materials. This sturdy and reliable machine is designed to streamline your recycling process, allowing you to save valuable time and space. With its advanced technology, it can effortlessly compress and bundle scrap iron cans, sheets, pipes, and tubes, ensuring maximum efficiency and cost-effectiveness. Our baling machine is built to last, with durable construction and easy maintenance, making it a smart investment for any recycling facility or scrap yard. Take control of your scrap iron recycling with our high-quality baling machine.

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

Introducing our Metal Sheets Pipes Stainless Steel Push-out Baling Press, the ultimate solution for efficient and effective baling of various metal materials. This high-quality press is designed to handle metal sheets and pipes made of stainless steel with ease. With its push-out mechanism, the baling process becomes a breeze, allowing you to save time and effort. The heavy-duty construction ensures durability and long-lasting performance, while the stainless steel material guarantees resistance to corrosion and wear. Whether you are in the manufacturing industry or a scrap metal collector, our baling press is the perfect addition to your operations. Invest in this reliable and efficient equipment today!

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

Introducing our high-performance Waste Aluminum Iron Steel Copper Scraps Baling Machine - the ultimate solution for efficient recycling and waste management. Designed to streamline your operations, this state-of-the-art baling machine effectively compacts and compresses various metal scraps, including aluminum, iron, steel, and copper, into dense bales, reducing storage space and transportation costs. Its robust construction and advanced technology ensure optimum performance and durability, making it a reliable asset for industries dealing with metal waste. With its user-friendly interface and customizable settings, this baling machine guarantees easy operation and maximum productivity. Join the sustainable revolution and revolutionize your waste management processes with our Waste Aluminum Iron Steel Copper Scraps Baling Machine!

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

Introducing the ultimate solution for professionals in the scrap metal industry - the Metal Leftover Stainless Steel Scrap Car Baling Press! This powerful and efficient machine is designed to streamline your operations and maximize productivity. With its robust stainless steel construction, it can effortlessly compress and bale leftover metal scraps, including stainless steel, from cars and other sources. The advanced technology ensures precise and uniform baling, saving you time and effort. Its compact design allows for easy installation and operation, making it ideal for any professional setting. Say goodbye to cluttered workspaces and hello to increased efficiency with the Metal Leftover Stainless Steel Scrap Car Baling Press!

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

Introducing our revolutionary Scrap Metal Shavings Turnings Chippings Baler Machine Press, designed to streamline your metal recycling process and maximize efficiency. This cutting-edge equipment is built to effortlessly compact and compress metal shavings, turnings, and chippings into dense bales, reducing storage space and transportation costs significantly. Its robust construction ensures durability and longevity, with a user-friendly interface that allows for easy operation and maintenance. With adjustable settings and a powerful hydraulic system, this baler machine offers unparalleled performance, delivering consistent results and high-quality bales every time. Upgrade your metal recycling operations with our Scrap Metal Shavings Turnings Chippings Baler Machine Press and witness the transformation in productivity and profitability.

$34000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y81T-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| warranty period | 1 Year |

| Machinable material | Brass / Copper, Alloy, Aluminum, Carbon Steel, Stainless Steel |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Bale Discharge Way | Side Push-Out |

| Warranty | One Year |

| Power Source | Hydraulic |

| Cooler | Water Cooler |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic/Manual |

| Press Force | 2500kn/250ton |

| Daily Output | 20~42ton/8h |

| Machine Weight | 19~27ton |

Introducing our state-of-the-art Aluminum Steel Iron Copper Metal Recycling Baler Machine, designed to revolutionize metal recycling processes. This robust and efficient equipment boasts a powerful hydraulic system, capable of compressing large quantities of metal waste into compact bales with minimal effort. By reducing the volume of metal waste, our baler machine optimizes storage space, transportation costs, and overall operational efficiency. Its durable construction, made of high-quality materials such as reinforced steel, ensures long-lasting performance and minimal maintenance requirements. With its user-friendly interface and advanced safety features, our Metal Recycling Baler Machine is an indispensable asset for businesses aiming to streamline their recycling operations while contributing to a greener future.

$16000 - 18000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y83L-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| Core component warranty period | 1 Year |

| Core components | Plc, Motor, Pump |

| warranty period | 1 Year |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic |

| Press Force | 2500kn (250ton) |

| Briquette Diameter | 100mm |

| Briquette Weight | 1~2kg |

| Machine Weight | About 5.5ton |

| Productivity | 3~4 Blocks/Min |

| Output | 2~3t/8h |

| Motor Power | 22kw |

$16000 - 18000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y83L-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| Core component warranty period | 1 Year |

| Core components | Plc, Motor, Pump |

| warranty period | 1 Year |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic |

| Press Force | 2500kn (250ton) |

| Briquette Diameter | 100mm |

| Briquette Weight | 1~2kg |

| Machine Weight | About 5.5ton |

| Productivity | 3~4 Blocks/Min |

| Output | 2~3t/8h |

| Motor Power | 22kw |

Introducing our cutting-edge Aluminum Chips Shavings Turnings Hydraulic Briquette Machine, designed to revolutionize waste management and maximize resource utilization. This high-performance machine efficiently compresses aluminum chips, shavings, and turnings into dense briquettes, reducing their volume by up to 90%. Equipped with a powerful hydraulic system, it effortlessly generates high-pressure force to shape the briquettes without the need for additional binders or additives. Our briquette machine ensures uniform size and density, facilitating easy storage, transportation, and recycling. By converting aluminum waste into compact briquettes, our machine not only minimizes storage space but also enhances the value of this recycled material, fostering a sustainable and eco-friendly future.

$16000 - 18000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y83L-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| Core component warranty period | 1 Year |

| Core components | Plc, Motor, Pump |

| warranty period | 1 Year |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic |

| Press Force | 2500kn (250ton) |

| Briquette Diameter | 100mm |

| Briquette Weight | 1~2kg |

| Machine Weight | About 5.5ton |

| Productivity | 3~4 Blocks/Min |

| Output | 2~3t/8h |

| Motor Power | 22kw |

Introducing our state-of-the-art Aluminium Chips Scraps Hydraulic Briquette Press Machine, designed specifically for professionals in the metal recycling industry. This robust and efficient machine is engineered to transform loose aluminium chips and scraps into dense, solid briquettes, reducing storage space and transportation costs. Equipped with a powerful hydraulic system, this briquette press machine exerts high pressure to compress the aluminium waste, ensuring maximum density and minimal moisture content. Its user-friendly interface allows professionals to easily control and monitor the entire briquetting process, ensuring consistent results every time. Our Aluminium Chips Scraps Hydraulic Briquette Press Machine is built to last, with a durable frame and high-quality components that guarantee long-term performance and reliability. Increase your productivity and profitability by investing in this innovative solution that streamlines your metal recycling operations.

$16000 - 18000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y83L-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| Core component warranty period | 1 Year |

| Core components | Plc, Motor, Pump |

| warranty period | 1 Year |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic |

| Press Force | 2500kn (250ton) |

| Briquette Diameter | 100mm |

| Briquette Weight | 1~2kg |

| Machine Weight | About 5.5ton |

| Productivity | 3~4 Blocks/Min |

| Output | 2~3t/8h |

| Motor Power | 22kw |

$16000 - 18000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y83L-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| Core component warranty period | 1 Year |

| Core components | Plc, Motor, Pump |

| warranty period | 1 Year |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic |

| Press Force | 2500kn (250ton) |

| Briquette Diameter | 100mm |

| Briquette Weight | 1~2kg |

| Machine Weight | About 5.5ton |

| Productivity | 3~4 Blocks/Min |

| Output | 2~3t/8h |

| Motor Power | 22kw |

$16000 - 18000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 Sets/Month |

| Model No. | Y83L-250 |

| place of origin | China |

| status | New |

| Video factory inspection | Provided |

| Mechanical test report | Provided |

| Marketing type | Ordinary Product |

| Core component warranty period | 1 Year |

| Core components | Plc, Motor, Pump |

| warranty period | 1 Year |

| Out-of-warranty service | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Quality | Iso9001:2008 |

| Place Of Origin | Jiangsu, China |

| Operation | Siemens Plc Automatic |

| Press Force | 2500kn (250ton) |

| Briquette Diameter | 100mm |

| Briquette Weight | 1~2kg |

| Machine Weight | About 5.5ton |

| Productivity | 3~4 Blocks/Min |

| Output | 2~3t/8h |

| Motor Power | 22kw |

$41000 - 46000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 sets/month |

| Model No. | Y83L-630 |

| Place Of Origin | Jiangsu, China |

| Quality | Iso9001:2008 |

| Operation | Plc Automatic/Manual |

| Motor Power | 30kw*2 |

| Press Force | 6300kn (630ton) |

| Work Efficiency | 3 Block/Minute |

| Weight Of Briquette | (7~9)kg |

| Size Of Briquette | D180mm (Customization) |

| Machine Weight | About 15ton |

| Shift Efficiency | 10-12.5ton/Shift (8 Hours) |

Introducing the "Alu-Crusher 3000" - the ultimate boss's dream machine! Tired of those pesky aluminum shavings cluttering up your workspace? Say goodbye to the mess and hello to efficiency with our Vertical High Pressure Aluminum Shavings Briquette Machinery! This beast of a contraption will transform those annoying shavings into compact briquettes faster than you can say "promotion." Not only will it keep your boss happy by tidying up the place, but it's also an excellent stress-reliever! Just imagine the satisfaction of watching those shavings get squished into submission. So, grab the Alu-Crusher 3000 today and briquette your way to the top!

$41000 - 46000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 sets/month |

| Model No. | Y83L-630 |

| Place Of Origin | Jiangsu, China |

| Quality | Iso9001:2008 |

| Operation | Plc Automatic/Manual |

| Motor Power | 30kw*2 |

| Press Force | 6300kn (630ton) |

| Work Efficiency | 3 Block/Minute |

| Weight Of Briquette | (7~9)kg |

| Size Of Briquette | D180mm (Customization) |

| Machine Weight | About 15ton |

| Shift Efficiency | 10-12.5ton/Shift (8 Hours) |

Introducing our revolutionary High Capacity Aluminum Shavings Briquetting System, designed to streamline your waste management process and maximize efficiency. This state-of-the-art system is built with a robust aluminum shredder that effortlessly transforms large volumes of aluminum shavings into compact briquettes. With its high capacity feature, it ensures uninterrupted operation and significantly reduces downtime. The aluminum briquettes produced are dense and easy to handle, making them ideal for recycling or resale. Our system is constructed with premium quality aluminum, ensuring durability and longevity. Experience a seamless waste management solution with our High Capacity Aluminum Shavings Briquetting System, and take your productivity to new heights.

$40000 - 45000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 sets/month |

| Model No. | Y83L-500 |

| Place Of Origin | Jiangsu, China |

| Quality | Iso9001:2008 |

| Operation | Plc Automatic/Manual |

| Motor Power | 22kw*2 |

| Size Of Briquette | 200*200mm |

| Weight Of Briquette | (9~11)kg |

| Press Force | 5000kn (500ton) |

| Work Efficiency | 3 Block/Minute |

| Machine Weight | About 12ton |

| Shift Efficiency | 12-15ton/Shift (8 Hours) |

Introducing the Square Briquette Aluminum Borings Briquette Machine - a game-changer in the world of recycling and waste management. This innovative machine is designed to efficiently convert aluminum borings into compact and easy-to-handle briquettes. With its square shape, it maximizes the briquette's density, making storage and transportation a breeze. The machine is equipped with advanced technology and a powerful motor to ensure high productivity and consistent briquette quality. Its user-friendly interface allows for easy operation and maintenance. By using this briquette machine, you can contribute to a greener environment while also reducing waste disposal costs. Invest in this cutting-edge solution and revolutionize your recycling process today!

$31000 - 34000 /Set/Sets

Product Details:

| Brand | Zhouzhuang |

| Packaging | nude packing |

| Supply Ability | 30 sets/month |

| Model No. | Y83L-500 |

| Condition | New |

| Warranty | One Year |

| Place Of Origin | Jiangsu, China |

| Quality | Iso9001:2008 |

| Operation | Plc Automatic/Manual |

| Motor Power | 22kw*2 |

| Work Efficiency | 3~4 Block/Minute |

| Machine Weight | About 11ton |

| Press Force | 5000kn (500ton) |

| Shift Efficiency | 5.5-7.5ton/Shift (8 Hours) |

Introducing our top-of-the-line Automatic Aluminium Chips Scraps Turnings Briquette Press! This high-performance machine is designed to efficiently convert aluminium chips, scraps, and turnings into compact briquettes, reducing their volume by up to 90%. Equipped with advanced automation, our press ensures a seamless and hassle-free operation, saving time and labor costs. The sturdy aluminium construction guarantees durability, while the user-friendly interface allows for easy control and monitoring. With its powerful hydraulic system, this briquette press delivers consistent and uniform briquettes, ready for recycling or resale. Invest in our Automatic Aluminium Chips Scraps Turnings Briquette Press and revolutionize your aluminium waste management process today!

Save time! Get the best deal

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.